St. Edward Road Proposal

FE 346:

Russ Foisy

Eric Forner

Matthew

Ghiorse

Bret Macaleer

Jeff Wale

March 12, 2001

St. Edward State park, Kenmore,

Washington

Table of Contents

Objectives (Matthew, Bret, and Jeff)

Site Description (Matthew)

Culvert Design (Nathan, Jeff)

Cross Drainage Design (Eric, Bret)

Curve Widening (Russ, Matthew, and

Eric)

Haul-time (Jeff, Matthew)

Ballast Design (Nathan Russ)

Clearing and Grubbing (Matthew)

Road Design (Bret)

Criterion

RoadEng

Costing

(Eric)

Objectives

Our main objective for this project

was to plot, traverse, stake out and cost a logging road in St Edwards State

Park. The primary function of this road is to transport harvested timber from

the landing site to a mainline.

Site Description

Our road site is located in

St.Edwards State Park, in Kenmore, Washington. It lies within sections 32 and

33,T.26n,R4E, and sections 4 and 5, T.25N,R.4E, W.M. Each member of the crew

team shared all responsibilities. The crewmembers were Nathan Werner, Russ

Foisy, Jeff Wale, Matthew Ghiorse, Eric Forner, and Bret Macacleer.

Culvert Design

Intro/Background

This crossing is being

installed because it is necessary to cross the creek in order to complete the

road decided in our FE 346 class. Due to

the fact that there are questions as to whether or not the creek could support

fish, the decision was made that the final design must allow for fish passage.

Culvert Design

Process Used in Design of

Culvert

The following, is the process and methods used in

determining an adequate culvert design. This process should be followed each

time a culvert design is undertaken, in order to account for all of the key

parameters.

Establish Givens/Assumptions

Side slope

ratios

Slope ratios for the culvert design have a direct

impact on the length of the culvert. For this reason, we used three different

slope lengths in order to aid us in deciding which would offer the most

advantageous results. There are no set slope ratios, but according to our specifications

we used 2:1 on either side of the curve over the stream. The steeper the slope the shorter the

culvert. The limiting factor here is that as the slope increases, cost

increases in order to minimize erosion. Although the 2:1 will erode the least with

minimal armament, the length of culvert is considerably longer. On the other

hand, if a 1:2 ratio is used, the culvert is much shorter, but the cost to

armor the slopes increases due to the need of retaining walls or rock gabions.

Assumed road width

The width of the road was assumed to be 26.2 feet

including the curve widening, in order to accommodate our design vehicle. The point of the crossing occurs at a curve

so that a 80 ft. radius was used in coming up with these specifications from

the info on curve widening taken from the 2.2 links, Forest Service Handbook

7709.56. The width of the road will also

act as a limitation on the length of the culvert, but cannot be varied.

Assumed height

of fill above culvert

The value of 14.5 feet from the flow line was also

taken into account to figure the total length of the culvert. We had to figure the added length do to the

2:1 ratio which added 58 feet to our culvert length.

Calculations

Stream

gradient

The stream gradient was estimated from the data

points and an estimated topographic map produced from Road Eng. The rise and run were measured in the section

of the creek where the culvert will be placed. The rise and run were then

divided to calculate a percent slope of 4%.

Length of

culvert

The total length of the culvert was figured through

means of the road and the side slope ratio and the total came out to equal 84.2

feet.

Discharge

values

The discharge values were calculated using the DNR

forest practices method. The Q

(discharge) values must be computed for the 100-year event for maximum passage,

and the 2-year event for the minimum flow and fish passage needs.

Equations:

Culvert

Dimensions

The dimensions of the culvert were calculated by

using the hydraulic charts for the selection of highway culverts prepared by

the U.S. Department of Commerce. The

arch culvert dimensions were 58inches by 36 inches.

Depth of water

in pipe

The depth of water in the pipe was calculated from

the dimensions of the culvert and the flow rate of a 2-year storm.

Velocity of

water in pipe

The velocity of the water in the culvert was

calculated using the equation Mannings Equation and then solving for V. From this we found that our velocity was 7.31

ft/sec which was found assuming the culvert was rectangular for the area that

the water reached. This value was not

appropriate for the fish to swim in because the velocity was to great. Therefore, we then assumed that we would put

in some boulders to slow the stream flow and got a knew value of n that equaled

.088 found in Environmental Hydrology book on page 223 table 7.5. From this assumption we then found a knew

velocity of 3.16ft/s which did meet the requirements of the fish to move up the

stream.

Hydraulic Drop

Since the culvert will be layed in at the same grade

as the stream bed, there will be no hydraulic drop.

Fish passage

Species

Although there are many possible fish species that

might use Miner Creek, the design fish is the trout that is < 6 inches.

Fish characteristics

The culvert is designed for a trout that is < 6

inches. This is because this fish is the limiting factor; all of the other

species can handle greater velocities and have similar needs in terms of depth.

This criterion was verified with Ken Bates of the Washington State Fish and

Wildlife Department.

Maximum

allowable flow velocities and depth requirements

|

Criteria: >6-inch adult trout |

Adult Pink, Steelhead |

Adult Chum Salmon |

Adult Chinook, Coho,

Sockeye |

|

Culvert Length (ft): |

Max. Velocity (ft/s) |

Max. Velocity (ft/s) |

Max. Velocity (ft/s) |

|

10-60 |

4.0 |

5.0 |

6.0 |

|

60-100 |

4.0 |

4.0 |

5.0 |

|

100-200 |

3.0 |

3.0 |

4.0 |

|

> 200 |

2.0 |

2.0 |

3.0 |

|

|

|

|

|

|

Flow Depth Minimum (ft): |

0.8 |

0.8 |

1.0 |

|

Hydraulic Drop Maximum

(ft): |

0.8 |

0.8 |

1.0 |

Table from WAC

220-110-070

It is clear that the maximum allowable velocity for

the flow in the culvert cannot be greater than 4 ft per second, for culverts

between 1 and 200 feet in length. This specific aspect will not allow this

design to pass fish because the culvert velocity is 13.8 ft per second.

Cost = 15.48*84.2+29.98*84.2

= 3827.73

Cross Drainage Design

Using

the following graph for determining cross drain spacing we came up with

3136.64kg per year being a tolerable sediment load and therefore considering

our average slope to be about 8% we used the cross-drain spacing of 60 m.

|

Climate

station: |

Sappho,

WA |

|

Buffer length: |

200

m |

|

Soil type: |

graveled

loam |

|

Buffer gradient: |

60

% |

|

|

|

|

Road width: |

4

m |

Average

annual sediment yield (kg)

|

Road |

Cross drain spacing |

||||

|

10 m |

30 m |

60 m |

120 m |

240 m |

|

|

2 % |

512.64 |

969.12 |

1840.36 |

4097.84 |

10334.48 |

|

4 % |

547.88 |

1136.80 |

2328.20 |

5722.04 |

15737.64 |

|

8 % |

608.56 |

1416.36 |

3136.64 |

8260.56 |

24350.16 |

|

16 % |

702.16 |

1848.84 |

4402.52 |

12162.32 |

36779.84 |

Sappho 8 E Snider Ranger Station,

WA USA -- August 1999

USFS Rocky Mountain Research Station, Moscow

Then

using RoadEng we put 18” diameter culverts of various lengths at skew angle of

60 degrees and sloped at –4%. A total of

10 cross-drains were put in. The arch

for the stream was already put in, but we added it in to our cost calculation

The

Total cost for the cross-drains was $4678.65

|

Culvert length |

install cost |

Furnish cost |

subtotal |

|

|

30 |

8.44 |

8.21 |

499.5 |

|

|

22 |

8.44 |

8.21 |

366.3 |

|

|

29.5 |

8.44 |

8.21 |

491.17 |

|

|

31.25 |

8.44 |

8.21 |

520.31 |

|

|

23.5 |

8.44 |

8.21 |

391.27 |

|

|

32 |

8.44 |

8.21 |

532.8 |

|

|

20 |

8.44 |

8.21 |

333 |

|

|

39 |

8.44 |

8.21 |

649.35 |

|

|

33 |

8.44 |

8.21 |

549.45 |

|

|

20.75 |

8.44 |

8.21 |

345.48 |

|

|

total |

|

|

4678.65 |

|

|

Stream arch |

|

|

3827.73 |

|

Grand

total 8506.35

Curve Widening

One

of the key elements to designing a low volume road is deciding on what sorts of

vehicles are going to be traveling on the road and how often. There are two main types of vehicles used in

the road design. There is the design vehicle, which will use the road the most

of any vehicle and should be able to travel the length of the road unassisted.

There are the critical vehicles, which will use the road only a few times and

may need help through trouble spots, such as filling in the ditch line to make

a tight curve.

In

our road design we have decided that the design vehicle is a standard log

truck. Our critical vehicles are a self-propelled yarder and a low boy

configuration large enough to bring in a loader.*

After

the road has been traversed and plotted, it is essential to ensure that all of

the vehicles that need to use the road at least once are able to get around the

curves. This adjustment is called curve widening.

A

standard road has a travel width of twelve feet. Due to the length and size of

the vehicles, all of them have there own specific traveling width especially

around curves. Therefore our first step is to calculate the curve widening

needed for each vehicle around each curve. This is done by establishing the

radius of the curve, knowing the central angle of the curve and using the specs

for the vehicle to attain a length.

Standard

log truck:

L = ![]()

L1 = wheel base

of truck

L2 = length of stinger

L3 = Bunk to

bunk distance minus the length of stinger.

Low

boy configuration:

L = ![]()

L1 = wheelbase of

truck.

L2 = distance from the 5th

wheel to the middle of the rear duel wheels for the first trailer.

L3 = distance from the 5th

wheel to the middle of the rear duel wheels for the second trailer.

*

All of the specifications for these vehicles can be found in the attached

appendices.

From

Figure 1 we can see that L1 is 6m which is 19.685 ft. L2

is 2.6m or 8.531 ft. L3 is 10.5m – 2.6m or 7.9m which is 25.92ft.

Therefore

Calculating L for the log truck:

L = ![]()

L = 31.408 ft

Calculating L for the lowboy:

L = ![]()

L = 46.25 ft

Our

first switch back has a radius of 60 ft and a central angle of 180°. Using the curve widening formula found in

Forest Service Handbook (FSH) 7709.56, 4.2 – 4.2txt fill.

CW =

Again

for the log truck we found

CW =

CW = 7.4 ft

These

calculations were done for each curve for the log truck and the lowboy.

We

found that there are no equation to find the curve widening for our yarder, so

we had the use a drafting simulator, which allowed us to represent a scale

model of our yarder and our curve. We then traced our yarder along the curve

and determined our curve widening for our scale representation.

Here

are our results:

|

Curve |

CW

for Log Truck (ft) |

CW

for Low Boy (ft) |

CW

for Yarder (ft) |

|

R

= 60 ft D

= 180° |

20.8 |

39.6 |

29 |

|

R

= 70 ft D

= 180° |

19.4 |

26.1 |

28 |

|

R

= 75 ft D

= 162.4° |

19.4 |

26.1 |

27 |

|

R

= 80 ft D

= 83.6° |

19.1 |

21.6 |

24 |

|

R

= 120 ft D

= 26.98° |

15.07 |

14.3 |

22 |

Table 1. Curve Widening

Results

As

we discussed our results we concluded that the low boy took precedence over all

the other vehicles in all of curves except, our 120 ft radius curve, due to the

large amount of curve widening needed.

Taper

is needed to integrate our curve onto our road:

The values we used for each curve are as

follows and were determined by Table 2:

|

Curve

Radius (ft): |

Taper

Length (ft): |

|

60 |

60 |

|

80 |

50 |

|

75 |

50 |

|

70 |

50 |

|

120 |

30 |

Table 2: Taper lengths

Curve

widening tapers should be straight lines before the point of curvature (PC) and

after the point of tangency (PT) for the following lengths:

Radius

(R)(feet) Taper Length (feet)

Less

than 70 60

70-85 50

86-100 40

Greater than 100 30

Haul Time

The

over all calculations found for haultime were calculated using the computer

program Otto Truck Simulator. In order

to use this program the following operations need to be performed.

First

the following road information must be obtained and recorded in a tab delimited

file from the road eng. map: Distance from beginning of the road to a point at

the beginning of a curve for each curve in the road in meters (straight lines

are considered a curve with infinite radius), the slope at the beginning of

each curve in decimal format, the radius of each curve (straight lines are

reported as a 99999 meter curve), the legal speed limit of the road section in

km/hr, and the surface type on a 1 to 10 rating (ratings can be found in the

Otto Truck Simulator instruction manual).

Next

the Otto program needs to be opened in DOS and the following information must

be inputted into the system: First truck specs are needed including engine and

transmission desired (these can be selected from the choices given from the

program), and the road file from the previous step must be imported as a ASCII

file. The program will then ask for gear

ratios and truck weights (weights will be needed for a loaded and unloaded

truck).

Once

all this information is inputted the Otto program will try to calculate

haultime. If the transmission does not

match the engine type or other problems the program will then inform you and adjustments

can be made.

The

following data will be supplied by Otto: Distance to the next station, time of

travel to the next station, speed between stations, power used, fuel

consumption rates, fuel consumed, rpm's, and the gear used between stations.

Ballast Design

Our

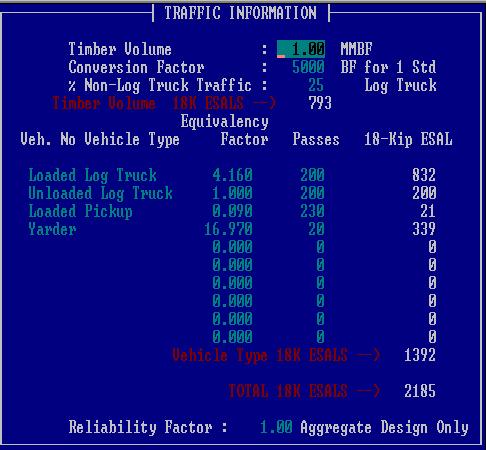

area had 1,000,000 Board feet and was logged in four years. The things taken into account were trips of

vehicles especially loaded log trucks, empty log trucks, yarders and

maintenance vehicles.

The

Log truck has a capacity of 5,000 board feet and will make approximately 200

trips over 4 years. The empty log truck

will make the same amount of trips and the maintenance vehicle will make

approximately 230 trips. Also, the

yarder will make 10 trips.

We

used a Surface Thickness Program from the Forest Service Department of

Agriculture. Table 1, Table 2, and Table

3 show the steps followed.

Table

1. Traffic Information. This information was given to us based on

usage of the road.

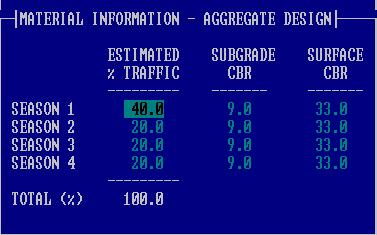

Table

2. Material Information. This contains the information on the soil

types at the site. The site had gravel

loam and from a compaction chart in Earth and Aggregate Surfacing Design

Guide for Low Volume Roads from the Forest Service (pg. 32), we figured

that it had a CBR of 9. Our Surface grade

is to be high end, so we are using a well graded crushed rock, which has a CBR

of 33.

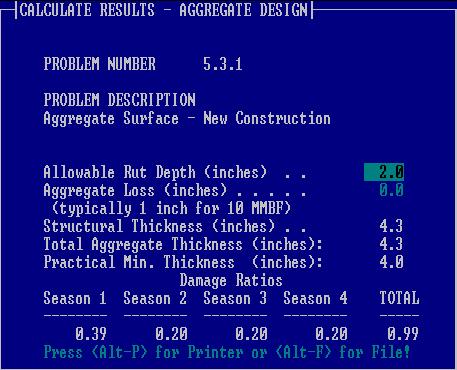

Table

3. Results. This takes the input from the first two

tables returns calculations here.

From

Table 3, we see that there should be a minimum grade thickness of 4.3

inches. We take this value to be 5

inches and then multiply by 2. The

maximum thickness of a particle is 5 inches and so the ballast thickness should

be twice that size giving us a thickness of 10 inches.

The

total volume of the ballast is 1172.2 cy3 (bases on RoadEng). The ballast cost is $7.50 per yd3. The cost to install it is $4.50 per yd3. This is a total of $12.00 per yd3.

The

total cost of the ballast installed is $14,066.40.

Clearing and Grubbing

Clearing is the process of removing (felling) timber from the right of way

Grubbing is the process of removing stumps/rootwads from the construction area

typically

a common cost value for clearing & grubbing is $ 600.-/acre

We

calculated the total surface area of our road, taking into consideration all

the curve widening, and calculated our road is 40,390 sq. ft. This converts to

.927 acres. From above we know that it costs $ 600 per acre to clear and grub.

This gives us a total of

Clearing and Grubbing:

$556.34.

Road Design

Criterion

The

Technical Use of the Criterion Survey Laser

The

laser while developed for timber cruising is very useful as a road survey

instrument. It can accurately measure horizontal distance, slope distance,

azimuth and percent slope. The laser also gives one the power to store the data

in the field; this reduces the human error involved in the relay of data from

the instrument operator to the note-taker. This also becomes rather enjoyable

when working in wet weather. This however does not mean that the laser is waterproof,

it can withstand a rainstorm, but do not throw it in a stream.

Equipment Needed To Operate

1. Criterion Laser

2. Reflector

3. Batteries and Cables

4. Foliage Filter

5. Shoulder Stock and Strap

6. A Competent Operator

Navigating the Criterion

Interface

The

criterion data display is limited to only two lines of text. Designated buttons on the control panel

controls the display. Up, down, and side

to side arrows allow the user to scroll through the text. Options are in folder type arrangement with

folders opening up to reveal other folders until a final selection is

made. Once an option is highlighted it

can be selected by pressing the 'Enter' button.

The 'Exit' button will take the user back to the previous folder.

Procedure for Criterion 400

(starting a unit survey)

1) Push the 'POWER'

button. (The word TREE should be displayed)

2) Use the up and down arrows to

Navigate; Go until you find SURVEY

and hit 'ENTER'

3) Then scroll until you find UNIT SURVEY and hit 'ENTER'. This will be displayed:

|

*SVY* |

(#) |

|

UNIT |

(#) |

(The asterisks can be moved

with the up and down arrows. Choose the numbers that you want to start with

preferably 1 and 1. Each unit number

will correspond to a saved unit survey.

The unit # cannot be zero or repeat something that has been saved)

4) When done use the down key to get to the next menu. (If

this does not work push enter then

the down arrow)

5) Scroll down to the screen:

|

*FROM* |

1 |

|

TO |

2 |

(This screen indicates the

point you are shooting from and the point you are shooting to. Each shot taken will create a point at the

target of the shot. Your first shot must

be a fore shot and will be from point 1 to point 2. Each side shot also counts as a point.)

6) Then down arrow until you see:

|

*FS* BS |

SIDE |

|

USER |

|

7) Make sure that the asterisks

are on the FS selection for the

initial shot. If it is not use the left

arrow button to select it.

8) Push the down arrow to see

the following screen:

|

HD: |

FT |

|

AZ: |

DEG |

(A shot can only be made

when the display shows this screen.

Otherwise the criterion will not take a reading.)

9) Take a reading at eye level

to approximately the same height on your partner or tree. Take first reading to the Left. To do this,

push the button on the hand trigger and hold it in. The longer you hold the

more accurate reading but shorter the battery life will become.

10) You have completed your shot

and can scroll up or down to view the data that has been collected.

11) Scroll until you find:

|

FS BS |

*SIDE* |

|

USER |

|

12) Push the orange

"SIDE" key (which is also the #5 key)

13) Scroll down to:

|

HD: |

FT |

|

AZ: |

DEG |

14) Take a side shot.

15) Push the orange 'SIDE' key

again to take another side shot.

16) Repeat this process to get

as many side shots as you like.

17) Scroll up to:

|

FS BS |

*SIDE* |

|

USER |

|

18) Press the 'INLINE' key. The asterisks should now be on the BS selection.

19) Place the criterion over the

next point in your road. (this should be

where your fore sight target was placed)

20) Use the down arrow once to:

|

HD: |

FT |

|

AZ: |

DEG |

21) Take your back shot.

22) Now you are ready to repeat

the process. Make sure that you follow

your back shot with a fore shot before shooting side shots.

23) Go back to step 1

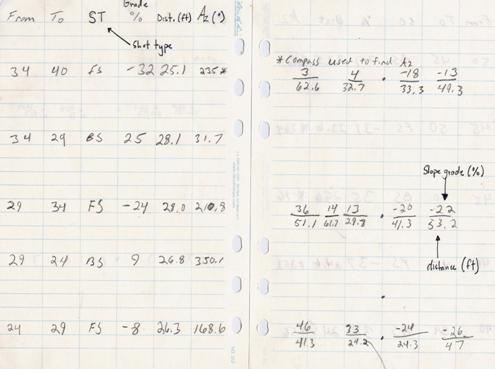

Note taking for the Criterion

· Set up your rite in rain notebook like the one shown in Figure 1 below.

·

Begin recording your data at the bottom of the left-hand page and work

your way up the page. *

·

Your first shot should always be a foresight.

·

After every Foresight, at least two sides shots should be

observed and recorded for data to calculate cross sectional areas. These shot

should be taken perpendicular to the road, and one taken in each the downhill

and uphill directions. These are the bare minimum required. You should take

more shots further away, or at different angles from the point. The flatter the

terrain, usually more side shots can be taken to acquire an efficient map of

the terrain. All of this information is recorded on the right-hand side of the

page. The essential information needed when taking side shots is distance, which gets recorded on the

bottom and slope grade, which gets

recorded on the top.

·

You then will proceed to the next point and there you take a backsight

to the previous point and then another foresight to the next point. Then repeat

above.

·

Be sure to leave ample space on the left-hand side of the notebook

between foresights and backsights. This allows enough room to on the right hand

side of the notebook to record your sideshots and any other pertinent notes

that need to be addressed.

Figure 1: example of field notes

RoadEng

Data Transfer

The

road data was transferred from an Excel file into RoadEng using the import

feature. The data came into excel in a

comma delaminated form. The FE Handbook

describes the following steps for creating a terrain model in RoadEng:

Transfer .pol files to RoadEng.

- Open Softree 98 then

select the Terrain mode.

- In the Terrain mode,

go to File and select Import

- From the small window,

select UNIT SURVEY and click on

Options.

- From the Options window, select the

following features and then click on OK.

- Softree will take you

back to the Import window, click OK.

- From the Unit Survey

window, find the .pol file that you saved and click on OK.

- Softree now creates

the plan view of your road.

If the plan view does not

resemble the layout of the site that was observed or the plan view seems to be

incomplete, the data obtained from the field needs to be rechecked.

- To calculate the

Terrain model, go to Edit

then select Calculate

Terrain Model and choose the following features and click on OK. This option from Softree will

calculate the contour lines on the Plan view of your road.

- A plan view the

contour lines is created from the Terrain Calculation option. You can adjust the contour intervals by

going back to Step 8 and changing the contour intervals. After the

contour lines are added to your plan view, save the file as a .ter file.

Terrain Module

In the Terrain module, errors in the data were

fixed. There were a few areas where

obvious mistakes had been made in recording the data. These areas were adjusted to the location

that we predicted them. During data

collection a connecting line was run from the end of the road to a control

point on the road. This line was removed

in the Terrain module. The data was transferred from the Terrain module to the

Location module. The following steps

were performed as found in the FE Handbook.

Transferring data to the Location mode.

- From the Edit menu, select Select Feature(s) and click on All.

- From the File menu, select Export Feature…and click on Ok.

- A Traverse Document

Export file window will be shown which allows you to save your file with

a .db1 extension.

- A warning window may

be shown notifying that the side slope extends outside of the Terrain

Model. Select OK.

- From Module, select to Location screen. From the File

menu or the open folder icon, select the .db1 file that you have created.

The Survey/Map screen opens the file in a similar format as the Field

notebook.

- To view the Profile

and cross sections of your road, select from the Module menu To Location Design. Select New

from the File menu or

click on the New icon

and a Select P-line traverse window will be shown. Find you .db1 file and click OK.

Location

Module

Windows

The majority of the design work

was performed within the Location module.

The four windows that were created were the plan, section, profile, and

data windows.

Profile window

In this window the gradeline

was adjusted according to the desired slope.

Here adjustments can be made to the vertical location of the road. Vertical curves were created to smooth the

transition between grades. A mass haul

subwindow was created here. This was

adjusted by creating mass haul waste locations.

Plan window

This window shows and

overhead view of the road. Here

adjustments can be made to the horizontal location of the road. Horizontal curves were created to smooth the

transition between straight-aways. This

window also shows the road width.

Section window

This window shows a cross

section view of the road prism. No

adjustments are made here in this view.

It is only for reference.

Data window

This window shows all data

sets in tabular format. The columns can

be chosen from the view menu.

Templates

Road prism templates were

created for each curve, straightaway, and taper. These templates were assigned to the proper

road locations. Here the road width,

ballast height, and side slopes were specified.

Culverts

Culverts were inserted into RoadEng

using the Edit Culvert function in

the Edit menu. The depth and length were adjusted here to

fit each location.

Costing

|

Clearing and Grubbing |

|

$556.34 |

|

Culverts and Stream Arch |

total = $8506.35 |

|

|

|

Culverts |

$4678.65 |

|

|

Stream Arch |

$3827.73 |

|

Ballast Costs |

|

$14,066.40 |

|

Haul time costs |

|

$811.37 |

|

Excavation |

|

$31,052.00 |

|

Grand Total |

|

$54,992.50 |

Appendix